Sciotoville Railroad Bridge

Article taken from The Portsmouth Daily Times, January 11, 2004

By William D. Middleton

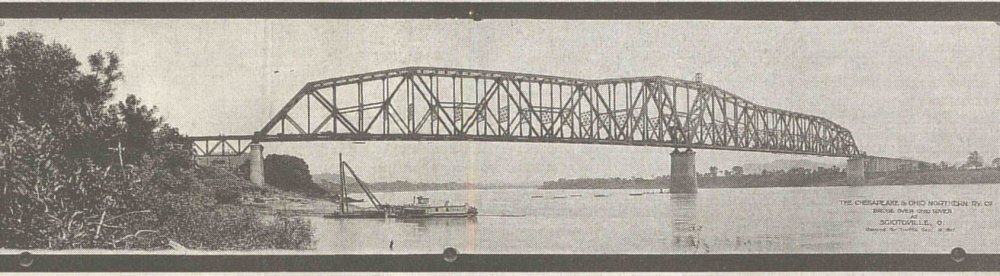

Although built in 1917, the Sciotoville Bridge over the Ohio

River remains the largest riveted truss bridge in America, stretching more

than a quarter mile in length. Its gargantuan scale can begin to be appreciated

with the realization that the antlike figures on the left span are workmen.

COLOSSUS on the Ohio

by William D. Middleton

Eighty-six years after its completion, the Sciotoville Bridge

over the Ohio River is still considered an engineering marvel.

The Ohio River flows past Ironton, heading north for more than twenty miles before making a sharp, right-angle, westward bend toward Portsmouth. Here, near a tiny community of Sciotoville, stands one of the wonders of the valley: a railroad bridge so gigantic that it merits the label "colossus." The single truss stretches 1,550 feet from end to end and at low water its highest point towers 236 feet about the river. It was an engineering marvel when completed in 1917 and still ranks among the great landmarks of American railroading.

Its story began with a search for new coal markets. At the beginning of the 20th century, the Chesapeake and Ohio Railroad was eager to extend its lines north and west across Ohio and Indiana to the Great Lakes and Chicago. The C&O had remained largely an eastern Kentucky, West Virginia and Virginia coal hauling line centered on the coal markets of the East. But the growing cities and industries of the Midwest had become major coal consumers as well and the railroad sought routes of its own into this new market.

In 1910, the C&O established a link to Chicago when it acquired a controlling interest in Chicago, Cincinnati and Louisville Railroad. A year later, a major component if a new route across Ohio to the Great Lakes was gained when the C&O took control of the Hocking Valley Railroad, which operated south from Toledo through Columbus to Athens and Gallipolis. But when the C&O attempted to complete the linkage through and additional merger, federal and-trust laws blocked the way.

The company soon hit on another scheme. The C&O incorporated a subsidiary, the Chesapeake and Ohio Northern. By building a new, 30-mile line north from Edgington, Ky., served by the C&O east-west main line in northern Kentucky, the company reached Waverly. From here, by acquiring trackage rights from other railroads, the C&O completed its linkage to Columbus. Constructions of the new line required crossing the Ohio River at Sciotoville. From the very beginning of the westward expansion of American railroads, the Ohio River presented a formidable obstacle that could be crossed only by means of record spans. The earliest was erected at Steubenville during 1863-64. Over the next half century, half a dozen other railroad crossings of the Ohio successively claimed the "longest simple span" record, culminating with the 723-foor main spain of a 1917 crossing at Metropolis, Ill. that remains the world's longest such bridge. The C&O's Sciotoville Venture would require yet another mammoth structure.

The continuous design of the Sciotoville Bridge trusses was daring

and novel. Continuous bridges are common as a type today, but historically

they were extremely complicated to analyze mathematically, especially prior

to the computer age. The computational labor alone limited their application

in America. Because the 1,550-foot trusses continued across a central pier,

the entire structure functioned as a unit, making possible the reduction

of the number of bridge components and their proportions. While the resultant

cost savings was significant in such a gargantuan structure, it was also

very risky unless used at sites like Sciotoville where the proximity of bedrock

ensured sold foundations.

Gustav Lindenthal

The railroad's inspired choice of a consulting engineer for the project, together with some unusual site conditions, created the opportunity for an innovatice bridge of an unprecedented scale. Gustav Lindenthal, the New Yorker chosen for the work, was a very accomplished bridge engineer. Born at Brunn, Austria (now Brno, Czech Republic), in 1850, Lidenthal studied at a technical school in Germany and worked on the Austrian and Swiss railway systems before immigrating to the United States in 1874. He served as bridge commissioner for New York City during 1902-03 and two of the city's great East River crossing into Manhattan and Queensboro Bridges, were among his many notable bridge designs. In 1907, the New York Connecting Railroad commissioned him to design the Hell Gate Bridge across the East River, which remains one of the city's signature bridges.

Lindenthal's staff for the Sciotoville bridge included two engineers who themselves ranked among the great American bridge engineers of the century. Swissborn Othamr H. Ammann, who was Lindenthal's principal assistant in general charge of the work, later designed such notable structures as the George Washington and the Verrazzano-Narrows Bridges. The equally distinguished career of David B. Steinman, who did the computations for the Sciotoville superstructure, culminated with his design of the 1957 Mackinac Straits suspension bridge.

Lindenthal, according to a biographical sketch prepared following his death in 1935, "never built two bridges alike." This stemmed from "his habit of looking on each bridge problem as new and unique," whose solution could hardly be the same as any previous project. He always sought "a conception of general form" before doing any calculations or working on details. he possessed in high degree "a gift of creative originality." Throughout his career, Lindenthal worked equally well with cantilever, arch and suspension designs. Each project had its own special site conditions and, just as at Sciotoville, he chose the design best suited.

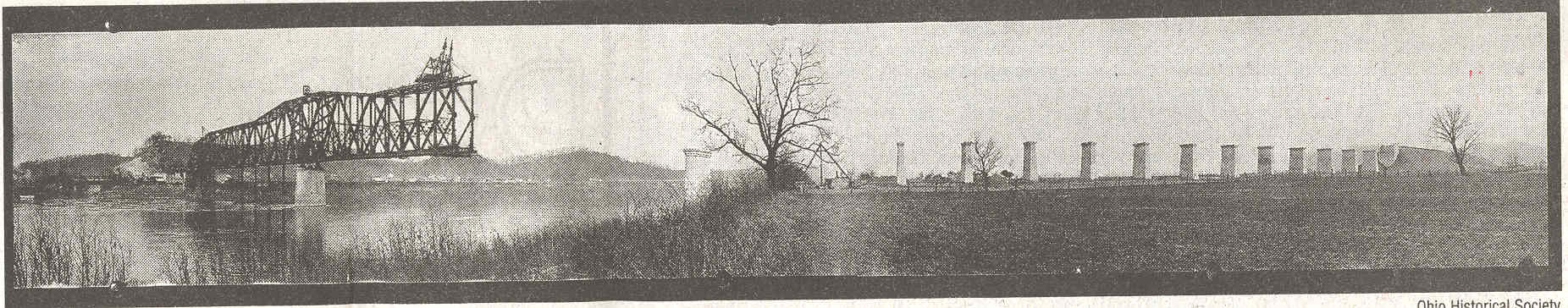

The enormous weight of the trusses at Sciotoville facilitated a requirement

that the shipping channels remain unobstructed during construction of the

bridge. After the Ohioside trusses were erected on temporary falsework, the

contractor used the weight of this half to counterbalance the remainder as

it cantilevered out toward the opposite shoreline.

Challenges

The Ohio was approximately 1,600 feet between embankments at Sciotoville. Chief among the special problems posed by the site was its location on a short curve. Normally, the navigation channel was on the Kentucky side of the curve, but it shifted to the Ohio side during floods. Consequently, federal regulations required two 750-foot clearances for navigation. While this might have suggested seeking an alternate location, the site had an important advantage as well. Solid shale rock underlay the mean low-water level at the center of the river by approximately ten feet.

This was a situation tailormade for a continuous truss bridge. In a bridge made up of two or more simple truss spans, each rests upon its end supports and each truss carries its load independently, gaining no support from the adjacent spans. But a continuous truss bridge "continues" over one or more intermediate piers, transferring a portion of the load over this entire structure. This enables the designer to reduce the sizes or quantities of truss members, producing a substantial savings in material.

Continuous design

Despite the potential advantages, American engineers had rarely used the continuous bridge form. Among their principal concerns were stresses created in such a structure through unever settling of the supporting piers. The solid rock foundation at Sciotoville negated this concern, enabling Lindenthal to design a continuous truss bridge that was a radical departure from standard American practice. He estimated that a continuous design would eliminate about 20 percent of the steel that would have been needed for simple trusses.

Lindenthal designed two enormous continuous trusses, extending 1,550 feet and crossing a center pier. They were spaced far enough apart to allow room for two tracks and were tied together by lateral bracing at the top and massive floor beams that supported the tracks. Each truss stood more than 129 feet high at the center pier, where the design required the strongest and largest quanity of steel, and gradually was reduced to a height of 771D 2 feet near the ends. The deck was 40 feet above the river's recorded high-water mark. North and south approach viaducts, totaling almost 1900 feet, linked the bridge to the railroad lines on either side of the river.

The steel structure could handle simultaneously a 426-ton locomotive pulling heavily loaded train on each track. This heavy design loading, together with length of the span, necessitated enormous sizes for some truss members. Some were more than seventy feet long, four feet square and weighed 144 tons. All the connections were riveted to ensure rigidity, another uncommon practice. Altogether, the bridge consumed some 13,200 tons of steel.

Construction of piers for the land approaches and the three main river piers required some 27,000 cubic yards of concrete and 425 tons of reinforcing steel. The substructure contractor, Dravo Contracting Company of Pittsburgh, began work on the main pier at the center of the river in October 1914 and did not complete until a year later.

Superstructure erected

Erection of the superstructure, which began in the spring of 1916, employed some unusual methods. The Ohio side of the continuous truss was erected on temporary supports that rested on the riverbed. The arrangement was not possible on the Kentucky side, where the channel had to be maintained for river traffic. Here, one important advantage of building a continuous truss came into play. While the Ohio side was being built from the center pier toward the shore on the temporary supports, the Kentucky side also was being constructed from the center toward the shore, but without any support underneath. With the continuous truss arrangement, the cantilevered Kentucky side was counterbalanced by the supported Ohio side. When the Kentucky cantilever was clear of the channel, temporary supports were added below the remaining construction and the bridge was completed.

The erection contractor, the McClintick-Marshall Construction Company of Pittsburgh, completed its work in time for C&O coal trains to being rumbling across the bridge in July 31, 1917. The span was one of exceptionally graceful lines, standing astride the river like some great steel colossus. Although some disputed his claimed material savings vis-a-vis a simple truss design, Lindenthal's peers were generous in their praise.

The bridge's success soon inspired a number of continuous long-span bridges for both railroads and highways in the U.S. and Canada. None, however have surpassed its prodigious dimensions, and the Sciotoville span today remains the longest continuous truss railroad bridge ever built.

Coal across the Ohio

For the C&O, the move into the upper Midwest coal market proved equally successful. A growing volume of Appalachian coal, marshaled at the company's Russell Yard in Kentucky, began to move north across the Ohio River over the new route, much of it destined for the Hocking Valley's Lake Erie coal docks at Presque Isle, near Toledo. Here, the coal was transshipped to U.S. and Canadian Great Lakes ports. The C&O expanded the Presque Isle facilities and by 1921 the docks were loading more than 4 millions tons annually onto Great Lakes steamers, rivaling the volume, shipped through the railroad's East Coast facilities at Newport News, Va.

In the mind-1920's, the volume of coal exceeded the capacity on the congested line between Waverly and Columbus, and the C&O set out to build a new line (completed in 1926) between the two points. The traffic continued to grow until well after World War II. By 1950, the C&O was hauling more coal to Lake Erie than any other railroad and in 1957 shipped a record tonnage of 18.7 million through the Presque Isle. Coal shipments across the Ohio have fallen since then with the decline of U.S. steel production and the discovery of new sources of low-sulfur western coal. But even so, 85 years later after its completion, Gustav Lindenthal's great Sciotoville Bridge remains a key link between north and south and a marvel of innovative engineering.

Members of the work crew who built the Sciotoville Railroad Bridge

gather around it.

Last Updated:

Wednesday, January 28, 2004 1:48 PM